In robotics and automation benefits of software simulation are apparent from early stages in the development life cycle of almost any product or system, and this is particularly true for industrial environments where equipment downtime periods are a key factor in the overall efficiency of a process. Today we take a look at RoboDK, a highly versatile development platform for industrial robot offline programming and simulation which supports over 200 industrial robots from leading manufacturers such as ABB, KUKA, Yaskawa, Adept and many more.

A bit of background, RoboDK is the commercial version of the perhaps better known RoKiSim robotic simulator developed at École de Technologie Supérieure (ETS) in Montreal, Canada by Ph.D. graduate Albert Nubiola. The software became pretty popular over its 3 years of existence so its creator founded RoboDK with the goal to create a more refined product for roboticists worldwide.

RoboDK is geared towards professional environments and is positioned as an offline programming solution for industrial robots. To better understand the benefits of this method we need to talk a little about teach pendant and lead through programming methods as well.

Both these methods require isolating the robot from its working environment for the entire period in which maintenance or reconfiguration is performed. Programming an industrial robot can become a quite time consuming task since multiple factors such as complexity of operations, energy efficiency, load or stress need to be taken into account. This stage has an important impact in the overall operating cost of a robot.

Another similar characteristic is that both these methods require human operators to maneuver the robot to desired location points that are learned. The teach pendant method involves a human operator manually driving the robot from a console using various coordinate systems (i.e. joint, tool, global etc.) to location points which are then stored for usage in the final program. The now obsolete lead through method involved a human operator physically moving the robot arm one position at a time, a task particularly difficult when working with heavy robots.

Offline programming is still not as widespread as teach pendant however it is rapidly gaining terrain thanks to its inherent advantages. Robotic equipment downtime is greatly reduced while complex software environments further aid development.

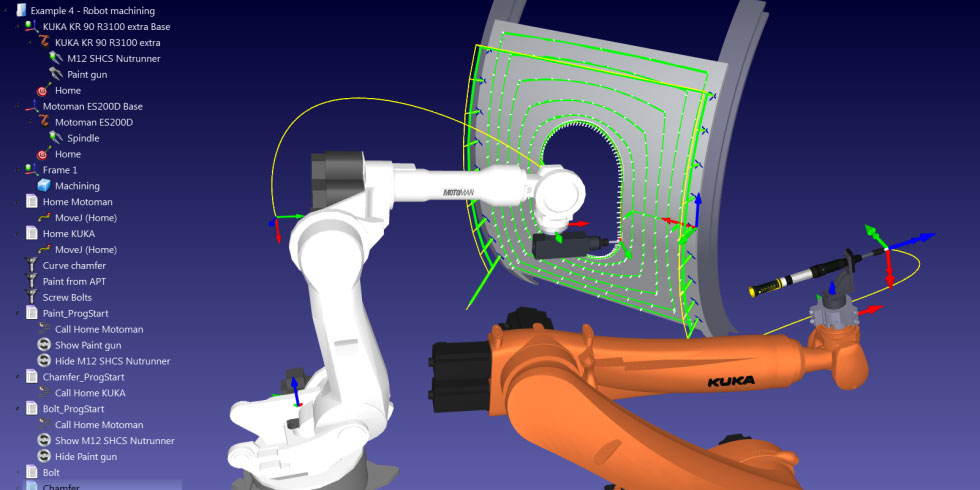

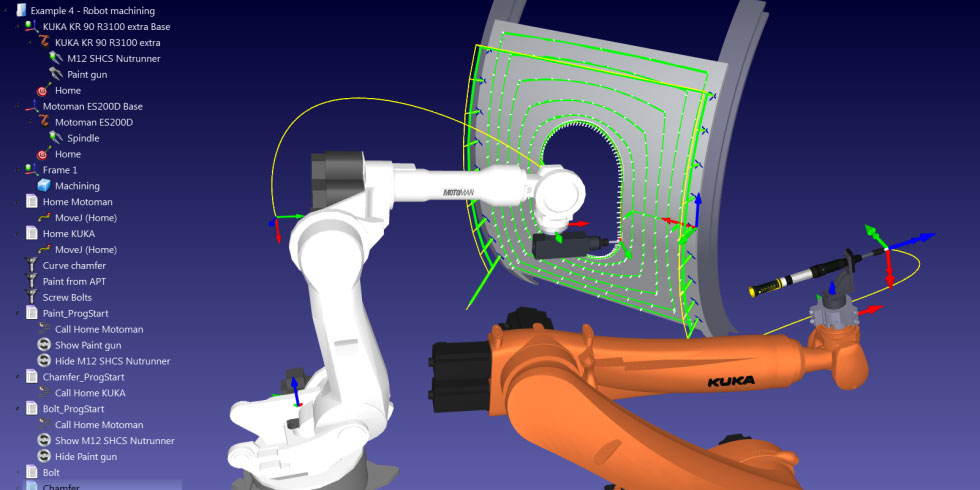

In RoboDK programs can be created either visually by using the integrated 3D simulation environment or by writing scripts in Python. Regardless of the method chosen the software can generate programs in robot specific languages – i.e. ABB uses RAPID, KUKA uses KRL and so on – so these can be easily uploaded to actual robots.

The 3D simulation environment offers many features, the user can play back a program and visualize every aspect of the robot behavior, the software generates alerts when robot singularities or possible collisions are detected, it allows the user to visualize the robot work space, optimize movements and avoid damage. The user can choose any reference plane when creating movements and can also have an overview of the whole technological process and program accordingly, an useful feature when the environment is more complex involving lots of interfering elements or even multiple robots. Right now the CAD model library consists of over 200 industrial robots, tools and external axes to choose from. Users can also design their own tools and customize the configuration of a chosen robot.

Accuracy testing and certification of robots can also be accomplished with RoboDK. A ballbar testing routine, better known as a method for calibrating CNC machines, can be selected and uploaded to the robot to check for accuracy and repeatability over time. This is useful for making adjustments to programs as wear and tear occurs to maintain peak productivity for the respective robot.

The software is well suited as an educational platform as well. Educators can set up demonstrations in class and students can perform experiments without fear of damaging otherwise expensive robot equipment. In fact the software can be used by anyone with an interest in industrial robotics regardless of their level of expertise. A set of workflow demonstrations can be viewed in the clips below.

The software is available as a free download for 32 and 64-bit versions of Windows, Mac OS, Ubuntu Linux and even Android.

Feel free to share your thoughts and impressions about this software or find out more information by accessing the resources below.

Resources

- RoboDK website

- RoboDK on YouTube

- Ballbar testing explained – Reinshaw

- Industrial robot programming methods – British Automation & Robot Association

- RoKiSim simulator