In order to build a mechatronic system that can achieve numerous functions and certain performance levels, designers must think outside the box when searching for solutions to be implemented, in almost every aspect, when building an intelligent machine. This also applies to the actuator system, where classical solutions may or may not meet certain requirements, established as being necessary. A relatively unconventional approach is the employment of piezoelectric or simply piezo actuators.

These actuators can be divided into several types:

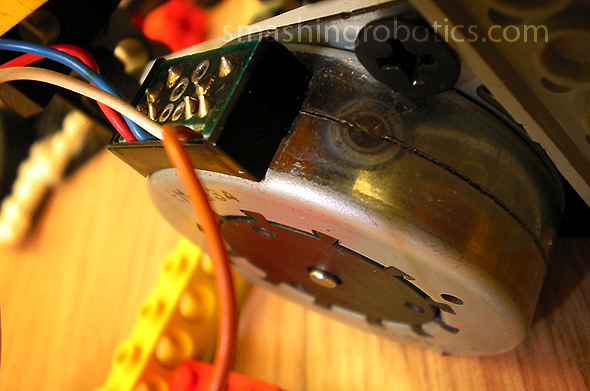

- Piezoelectric actuators – usually employed for controlling fuel injection in internal combustion engines;

- Electrochemical actuators – found in airbag expansion systems;

- Artificial muscles – employed for mobility and manipulation features in humanoid robots;

- Shape memory actuators – found in robotic hands, actuating the artificial fingers.

The range of unconventional actuation techniques is much larger, continuous development taking place in the area, including other types of actuators based on electrostatics, electro and magnetorheology or magnetostriction principles. It is not uncommon for the most unexpected and unconventional solutions to be the key factor in the success of a certain product.

Benefits of piezo actuators

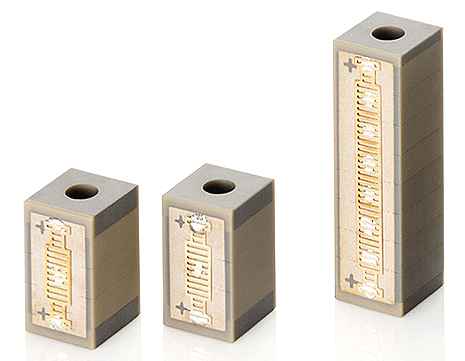

Piezoelectric actuators have the following attributes:

- They have a theoretical unlimited resolution, often resolving to sub-nanometer values, i.e. smallest changes in supply voltage are detected and converted into linear motion without skipping or stepping;

- High actuation forces can be attained without significant loss in precision, for instance loads higher than 10.000 Newtons can be positioned with micrometer accuracy;

- Extremely high response times of under 1 millisecond. As an example, the elongation response of a piezoelectric actuator can be limited only by the speed at which sound is propagated through ceramic materials. Accelerations several thousand times higher than gravitational acceleration (G) can be attained;

- There are no moving parts and thus no friction or free play. Elongation of a piezoelectric actuator is based only on deformation of the material and there is also no fatigue or aging involved. Endurance tests have proved that there is no altering in such an actuator’s operation even after 500 million cycles;

- Very low power consumption as the piezo effect converts energy directly into motion, the execution element absorbs energy only when elongating;

- No magnetic fields are generated when the actuator is operating.

Such advantages have made piezo actuators very popular in several domains as:

- Precision mechanics and Mechanical engineering – found in adjust and extrusion tools, correction of wear and active control in tools injection nozzle control, micropumps, piezo hammers, micro etching, active vibration cancelling systems, micro and nanorobots;

- Optics and measurement systems – employed in rapid scanning and positioning of mirrors, holography, interferometry, laser sweeping, fiber optics positioning, image stabilization, active adaptive auto focus;

- Medicine – micromanipulation and microsurgery, cell penetration, microdosing systems, physiological stimulations, shock generation;

- Microelectronics – Mask positioning, microlithography, inspection and control systems.

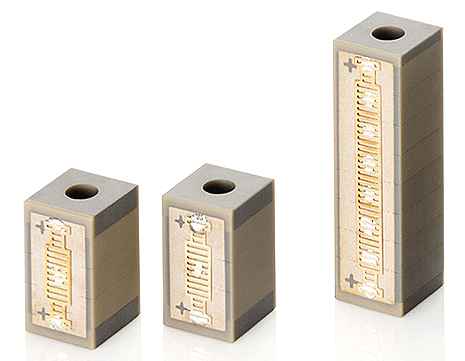

Principles of operation

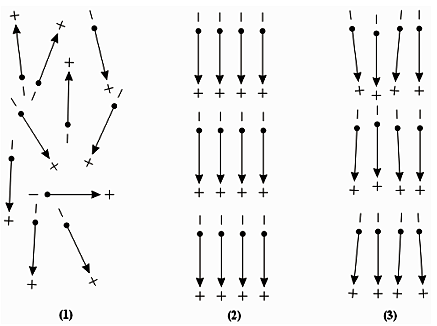

A piezoelectric actuator is an electrically controlled positioning element that functions based on the piezoelectric effect. The direct piezo effect, employed for instance in piezoelectric force sensors, represents generating an electric charge as an effect of mechanical strain. Actuators are based on the reverse effect, namely and electrical field parallel to the direction of polarization, determines an elongation of the crystalline material with respect to the same direction. The electrical field generates a torque over the electrical dipoles found in the structure of the material, which will be aligned along the field, producing in turn a change in the length of monocrystalline partitions.

However in natural monocrystalline materials, such as quartz, tourmaline, Rochelle salt, and so on, the piezoelectric effect has small ampleness so that synthetic polycristalline ceramic materials with superior piezoelectric have been developed, such a material being lead zirconate titanate (PZT). These materials are produced in a wide range of variants and are widely employed in piezoelectric actuators manufactured today.

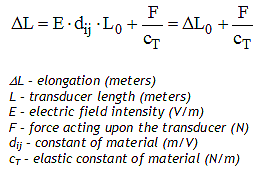

A piezoelectric transducer is an actuator that elongates when subjected to an electrical field. This elongation is dependent to the ceramic material employed, its length, intensity of the electric field and force acting upon it. An expression to summarize this is:

Maximum elongation is limited by the intensity of the electric field at which the actuator can be subjected without being destroyed by tension shocks, limits usually around 1-2 kV/mm. A transducer is an elastic body with a certain rigidity, same as any other solid. If compressed with a certain force F, it will be compressed with the amount of force divided by the specific constant for the material.

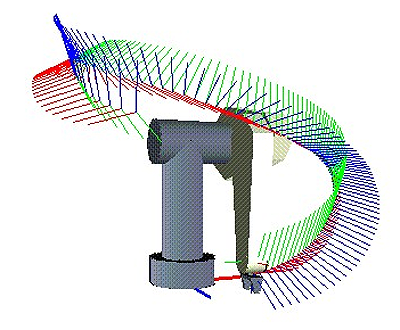

Two types of behavior of a piezo transducer can be identified, based on the type of strain it is subjected at:

- Constant load (F constant) – in this case the force is usually exerted by a weight that remains constant during the elongation process of the actuator. Since elongation capabilities are not affected by load, maximum elongation will be the same as when the material is not mechanically stressed, but the zero point of the positioning domain will be displaced down with the value F/constant of material;

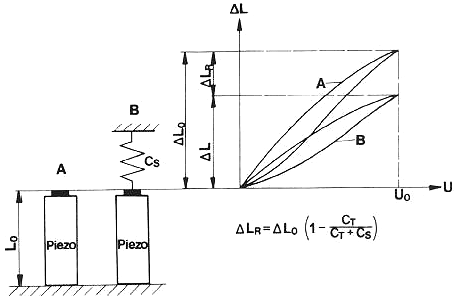

Figure 2 – Piezo transducer under constant load - Variable load (F as a function of elongation) – here force is dependent to the elongation of the piezo material. All application in which a positioning element acts upon a spring or an elastic wall find themselves in this category. The more rigid the elastic obstacle – spring or elastic wall – with higher elastic constant Cs, the less travel is available to the transducer.

Figure 3 – Piezo transducer under variable load

Actual elongation will be:

As it can be seen in the graphical representations above, the elongation of a transducer is not linearly variable with supply voltage, but rather a hysteresis curve, with different values as voltage rises or decreases. The hysteresis phenomena is determined by crystalline polarization effects – as seen in figure 1, diagrams 2 and 3 – and molecular effects, maximum values of this effect are around 10 to 15 percent of the desired travel. These values translate into errors in the micrometer domain, and can be insignificant in certain applications. If more precision is required a closed-loop control of elongation can be implemented, by means of a position reactive system.

Dynamic behavior

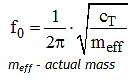

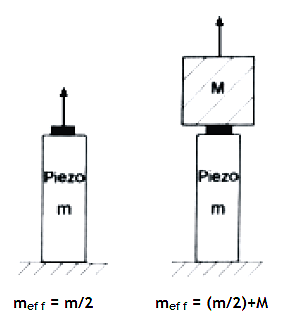

A piezo actuator can reach its designed elongation in a time equal to one third of its resonant frequency cycle. The resonant frequency of an unstressed transducer is of several tens of kHz for travel in the range of micrometers and several kHz for travel higher than 100 mm. A supplementary load will lower the resonant frequency according to the expression:

The actual value of mass can be inferred from the representation below:

Conclusions

A piezoelectric transducer is similar in operation to a capacitor. As losses through a ceramic insulating material are very low – such a material can cope with up to 10 MW power – it can be said that, in static conditions, a piezo actuator does not use energy and does not dissipate heat. Dynamically the power consumption varies linearly according to frequency and capacity of the transducer, for instance a transducer with a 15 mm travel and a 10 kg load capacity, employed at 1 KHz consumes a few Watts, while a transducer, at the same frequency, that has a load capacity of several tonnes, will absorb a few hundreds of watts.

Resources

- Piezoelectric actuators, NDT Education

- Piezo actuator products, Physik Instrumente

- Piezoelectric ceramics, APC International

- Piezo technology, Siemens

- Piezoelectricity, Wikipedia