by Sven Schmidt-Rohr

Until recently robot programming was characterized by three different, typically very distinctively deployed programming techniques: teach pendant programming, graphical offline programming and textual programming.

Teach pendant programming is the simplest method, performed online directly at the location of the physical robot. By means of buttons and joysticks, a user can move the real robot into different states of its joints and/or pose of its end-effector. The user can record such poses one after another and then select different modes to connect these poses into a continuous robot motion trajectory (path).

Since this method is very straight-forward, it cannot use information about the work cell or parts to help the human find faster, more optimal paths. Furthermore, it does not work with more complex logic to let the robot react flexibly to signals of force-torque sensors or industrial cameras. As a result, teach pendant based programming is only suitable for the most simple industrial robot usage scenarios.

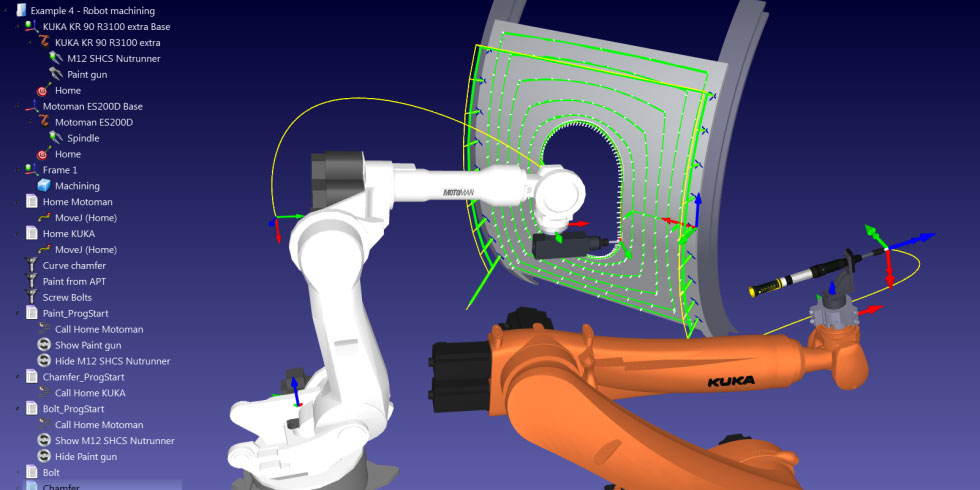

Graphical offline programming reaches a step further by taking into account robot workcell and workpiece geometries as well as helping to compute optimal robot trajectories. Such graphical offline programming software is more powerful, but also more difficult to use. Thus, you need a solid CAD/CAE background to fully comprehend the interfaces of the software, focused on typical offline programming. The software can then load the CAD models of the planned robot workcell as well as workpieces, based on which robot motion programming can take place in the office, far away from the actual production line. The software allows to define and modify waypoints more quickly than possible with teach pendant programming. It also supports finding optimal motion profiles for the fastest possible execution time. Advanced tools provide automatic, collision-free motion planning to compute valid and fast trajectories in a fully automated manner, given complete CAD geometry descriptions of the work cell. Yet, there is often still a rough stage from the virtual program generated by the robot towards the real robot executing the task robustly. Reasons can be calibration or model deviations, but also last-minute changes on the shopfloor. This “shopfloor-disconnection” is a big problem with most offline-programming offerings.

Anyways, complex logic, reacting to sensor readings as well as flexible robot behavior cannot be modeled with your typical offline programming suite. Those modern, flexible robot applications must be programmed directly in the programming language of the robot vendor. This approach needs extremely extensive expertise in both textual software engineering as well as sensor-based robot applications. Required personnel is very hard to find, but even they need hundreds of hours on average to program such flexible robot applications.

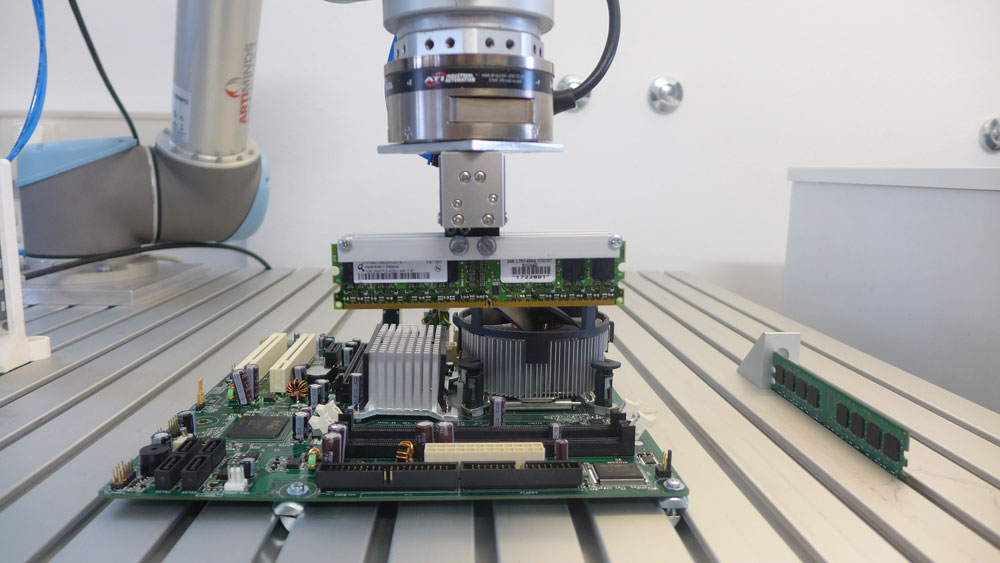

Since 2015 however, ArtiMinds Robotics has introduced a novel robot programming software product into the market which combines the strengths of those three classical approaches while getting rid of their weaknesses. The ArtiMinds Robot Programming Suite (RPS) allows for an arbitrary mix of direct programming at the physical robot with graphical offline programming, while providing very intuitive, complete access to complex, force-torque or computer vision based flexible robot motion behavior.

The programming process uses three basic steps:

- Drag-n-drop of motion segments by type, called templates, e.g. “soft putting down”, “force-controlled insertion”, “aligning surfaces by force-control” or “collision-free motion planning segment”.

- Teach-in of a few key poses per template. This can be done either by teach-pendant at the real robot, by guiding collaborative robots directly at their wrist or in the 3D-environment of the offline programming graphical user interface.

- Computation of nominal trajectories, force controllers, simulation of the task and finally translation into the native program code of the target robot. This code runs stand-alone and the computer with the RPS can be unplugged after programming.

By these means, the user does not need to have knowledge in textual programming, while the offline programming interface is also heavily simplified. Teach-in at the real robot on the shopfloor and teach-in in simulation can be arbitrarily intertwined or alternated, leading to much more integrated offline and online programming. Furthermore, developed template sequences for certain processes can be reused much easier for similar applications. Force-controlled applications are widely accessible with external benchmarks by system integrators with much experience in force-controlled robot applications, showing even experts programming 100 times faster with the ArtiMinds RPS.

The software integrates various industrial robots, force-torque sensors, grippers and computer vision platforms, so that the programmer can focus exclusively on developing the optimal robot application process, instead of dealing with the typical software integration issue.

ArtiMinds Robotics is specialized in developing advanced algorithms for robotic manipulation, taking advantage of the latest research in industrial and autonomous robots. The company was founded in Karsruhe, Germany receiving numerous awards since 2013 for its products.