Today robotic arms are employed on a large scale, for an endless list of applications. You can find robotic manipulators almost everywhere, in industrial environments performing highly repetitive or heavy duty manufacturing activities on assembly lines, in research facilities precisely handling sensible or hazardous substances or objects and even on other planets gathering samples or otherwise. There are few activities a robotic arm cannot handle, successfully increasing productivity and precision or seamlessly operating in environments not suited for humans. Robotic arms are generally designed to replicate a human arm so they are relatively similar in structure, however there are countless variations of design depending on applications for which they are specifically built. Compared to a human arm robotic arms can have reduced or elevated complexity and abilities in terms of movements they can perform and loads they can carry.

A primary criteria that defines a robotic arm is the number of degrees of freedom (DOF), each degree of freedom representing a motion a robot can perform. For a robotic arm to perform a motion it requires a joint which allows either rotational or translational movement, and of course an actuator to power that section, therefore the number of DOF can be easily determined by establishing the number of actuators in a robotic arm. The more DOF the better, as the robotic arm can perform a greater range of movements. Each DOF however has a great impact on the complexity, not necessarily in terms of the robotic arm’s structure but rather in terms of the mathematical models describing it. These models can be extremely complex and can absorb a huge amount of resources so it is recommended to implement the minimum amount of DOF possible required for an application as everything, needs to be taken into account when developing motion algorithms in order to reduce unwanted or potentially hazardous operation to a minimum.

Another criteria is the workspace of the robotic arm which is comprised by absolutely all positions its business end, i.e. gripper or tool that directly performs a task, can occupy or reach in an environment. This is important as the robot must be able to reach what it should operate onto, as well as stand clear of everything else in the environment. Other factors defining a robotic arm are extremely dependent to application and include sensor arrays, load capacity, joint forces, power sources or types of actuators. For more information you can read our dedicated articles about industrial robots.

Although robotic arms employed in industrial or otherwise professional environments can be in the price range of tens and even hundreds of thousands of dollars, slightly out of reach even for some institutions let alone a home user or developer, the market for light duty affordable robotic arms is continuously growing as robot manufacturers have developed budget alternatives for hobbyists or professionals alike. In this series of articles we will discuss about sub-1000 dollar robotic arm kits.

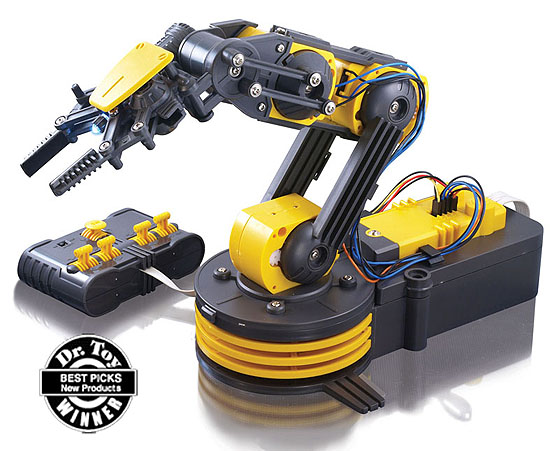

OWI Robotic Arm Edge Kit

The OWI-535 Robotic Arm Edge kit is perhaps the most inexpensive product on the market. With a price of around 60 US Dollars, this very affordable robotic arm kit is aimed at beginners in the field of robotic manipulators. The robot is not programmable but rather operated via a wired remote control, however with a few clever electronics it could be easily interfaced with an electronic brain. The plastic kit comes disassembled with only basic tools required to put it together. The arm has 5 DOF, including the gripper, and has a lifting capacity of 100 grams. It also comes with a LED light source at the gripper and audio warnings for all 5 actuator transmissions in order to avoid damage to the gears.

The gripper can open and close, it wrist has a motion range of 120 degrees, the elbow range is 300 degrees, the base can rotate 270 degrees vertically and rotate 180 horizontally. The robot has a vertical reach of 38 centimeters and a horizontal reach of 32 centimeters. The robot has a mass of 658 grams and requires 4 D-type batteries to be powered up.

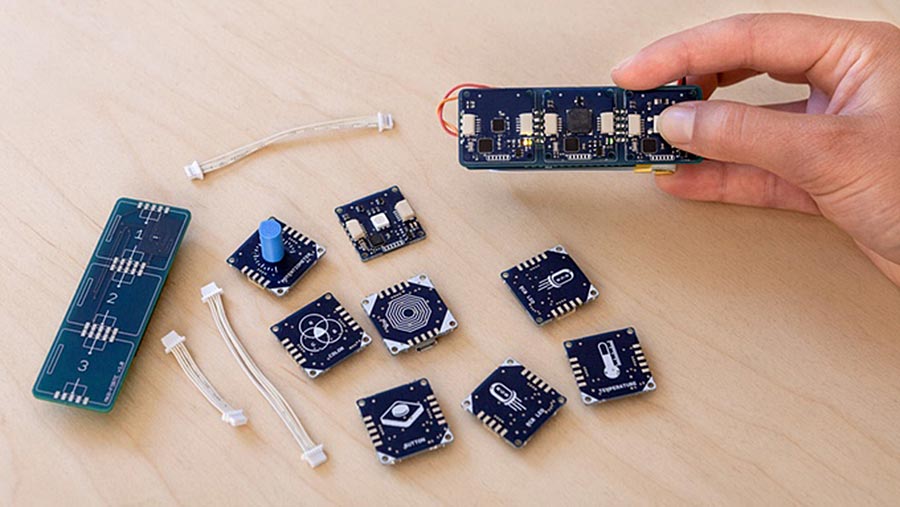

Dagu 6 DOF Robotic Arm

The 6 DOF robotic arm from Dagu is more complex and has a more robust structure. As its name implies, it has 6 joints and its structure and gears are all made of aluminium. The fully extended arm has a length of 39 centimeters and can is actuated by 4 12 kg*cm (1,17 Nm) metal geared servos for base and arm and 2 1,8 kg*cm (0,17 Nm) micro servos for the gripper and wrist.

It is controlled by an ATMega168 microcontroller mounted on an Atrexx mainboard which can control up to 32 servos, making the kit very expandable. The mainboard also comes with an RS232 serial port for communicating with the computer and also supports expansion with a WiFi module. The robotic arm kit also comes with a PC software suite, including a controller and an interface to upload your programs to the robot. It can be bought at a price of around 280 US Dollars.

TROBOT 4.0

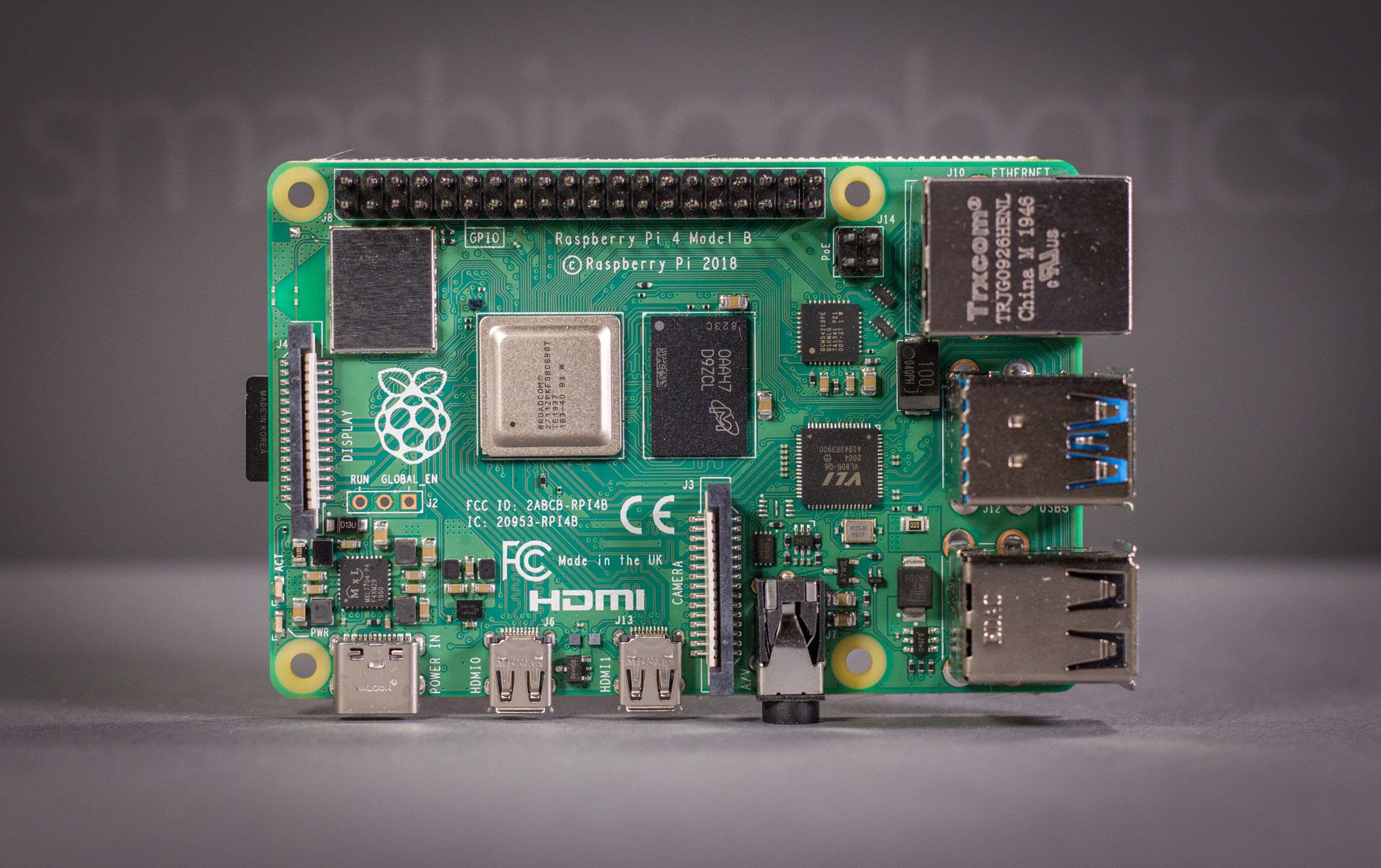

The now commercially available TROBOT 4.0 was a project started by industrial robot control engineer Toby Baumgartner. This project aimed at replicating a large industrial robot at a reduced scale. A very interesting fact is that the developer managed to control the TROBOT with the ABB RobotStudio software, while redesigning control electronics with the mbed platform, complete with an Ethernet interface to control the robot from a PC.

The 6 DOF TROBOT 4.0 construction kit itself is available for 250-300 US Dollars, while servo kit and required accessories are available for another 600 US Dollars.

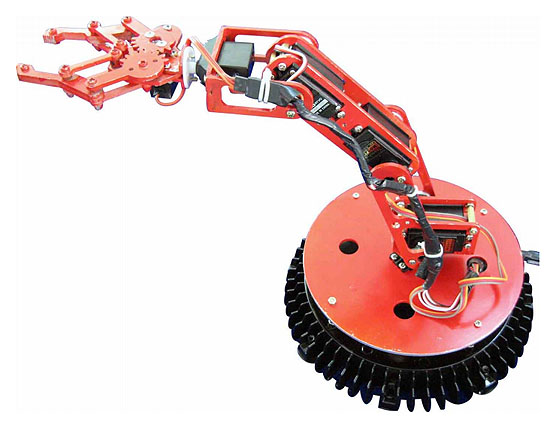

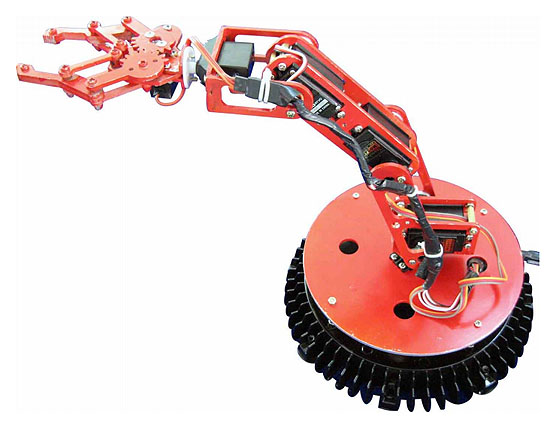

ServoCity Stacker Robot Kit

The Stacker robot kit from ServoCity is essentially a robotic arm with wheels. The arm itself has 2 DOF with 2 more added by the differential drive rolling base. A complete kit, including electronics and remote control, can cost a little over 300 US Dollars making it very accessible for educational and experimental purposes. Its structure is made of ABS plastic and has a weight of about 1,3 kilograms fully equipped.

It has a length of almost 30 centimeters with the arm fully extended. The robot employs 2 continuous rotation servos for the wheels, a standard servo for opening and closing the gripper and the HS-785HB 3,5 turn servo for the lift arm.